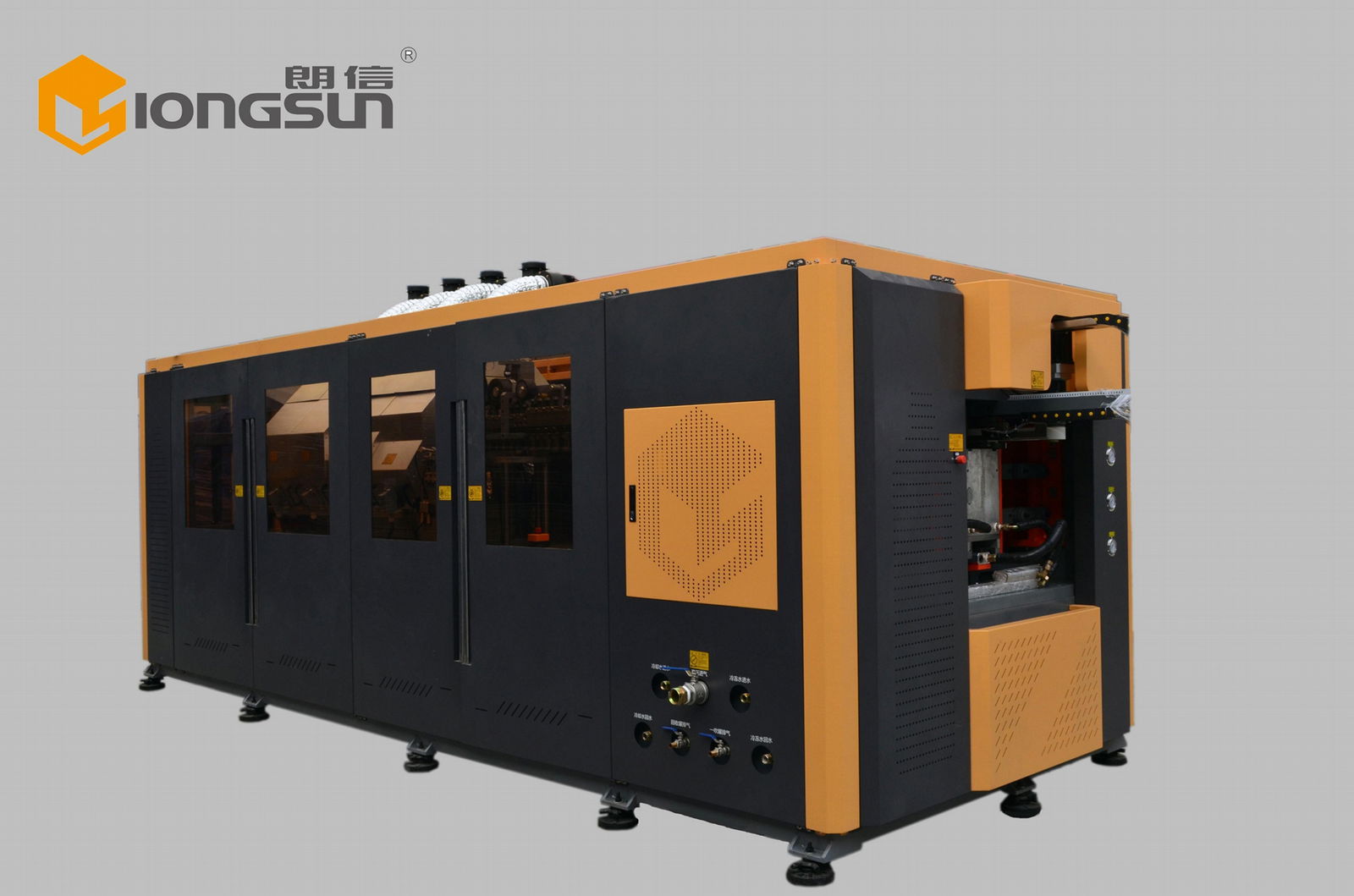

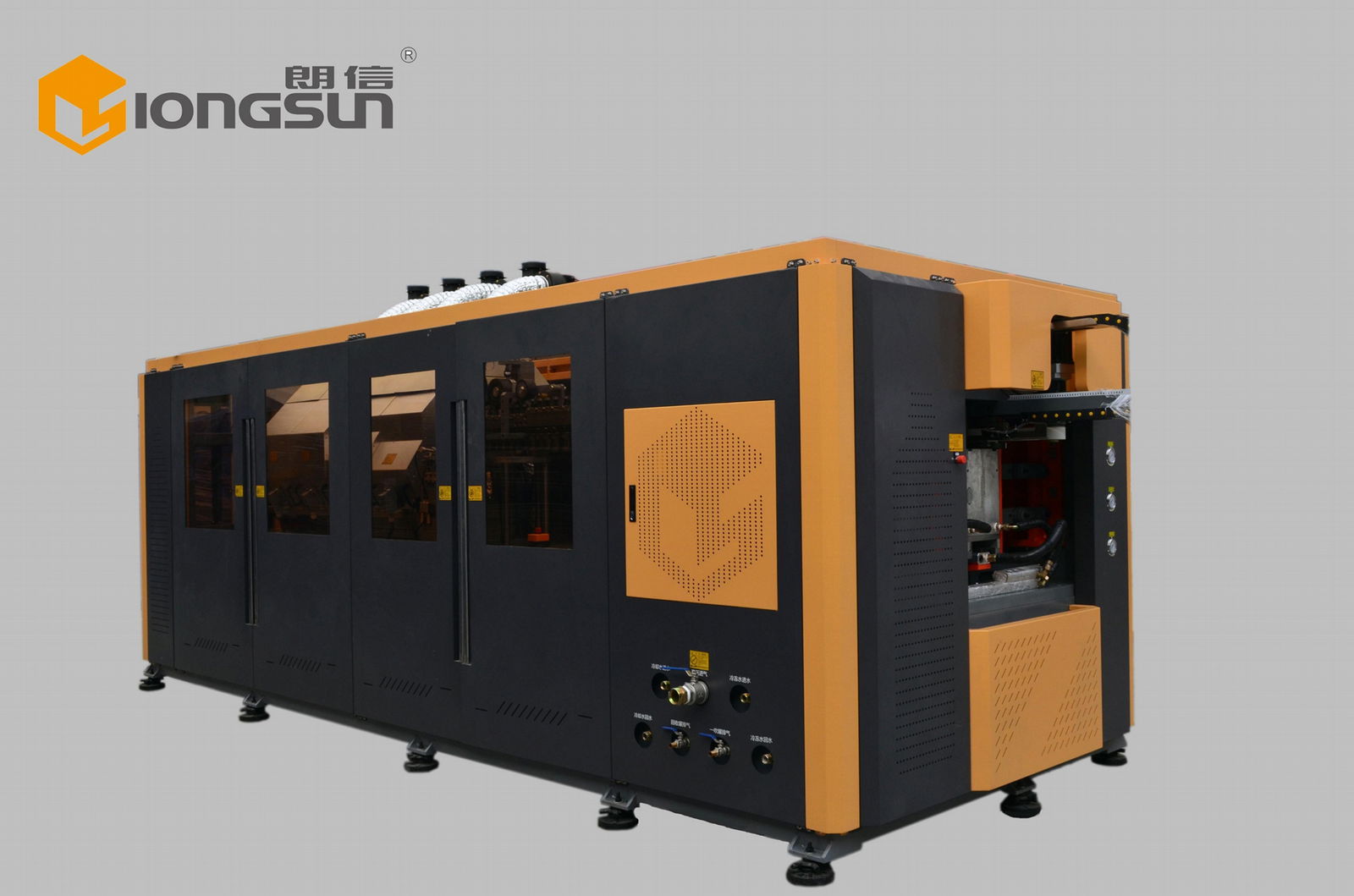

Product Description

LXG- 4/5 Auto Bottle Blowing Machine Feature

Lxg-4 / 5 is a PET bottle blowing machine with capacity of 5L and below designed by Longsun. The output is stable at 4000 bottles / hour. It is suitable for blowing mineral water bottles, edible oil bottles and other packaging containers!

The all electric structure make the machine to run stably and at high speed, with precise positioning. It is equipped with a full-automatic mechanism for processing the upper preform, a one way preform loading structure and a preform detection device, which can automatically remove the unqualified bottle preform and ensure the efficiency of the whole machine blowing the bottle.

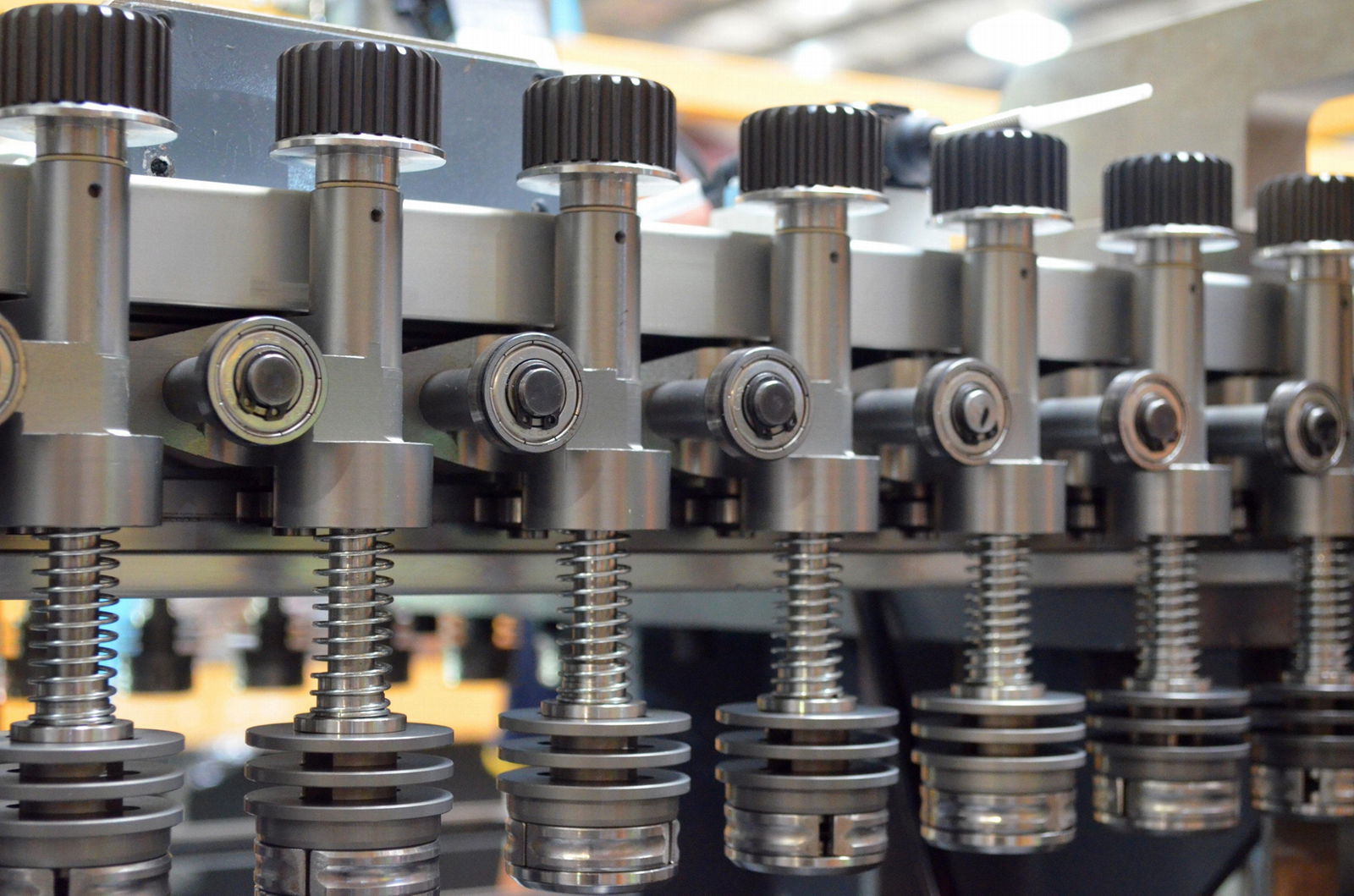

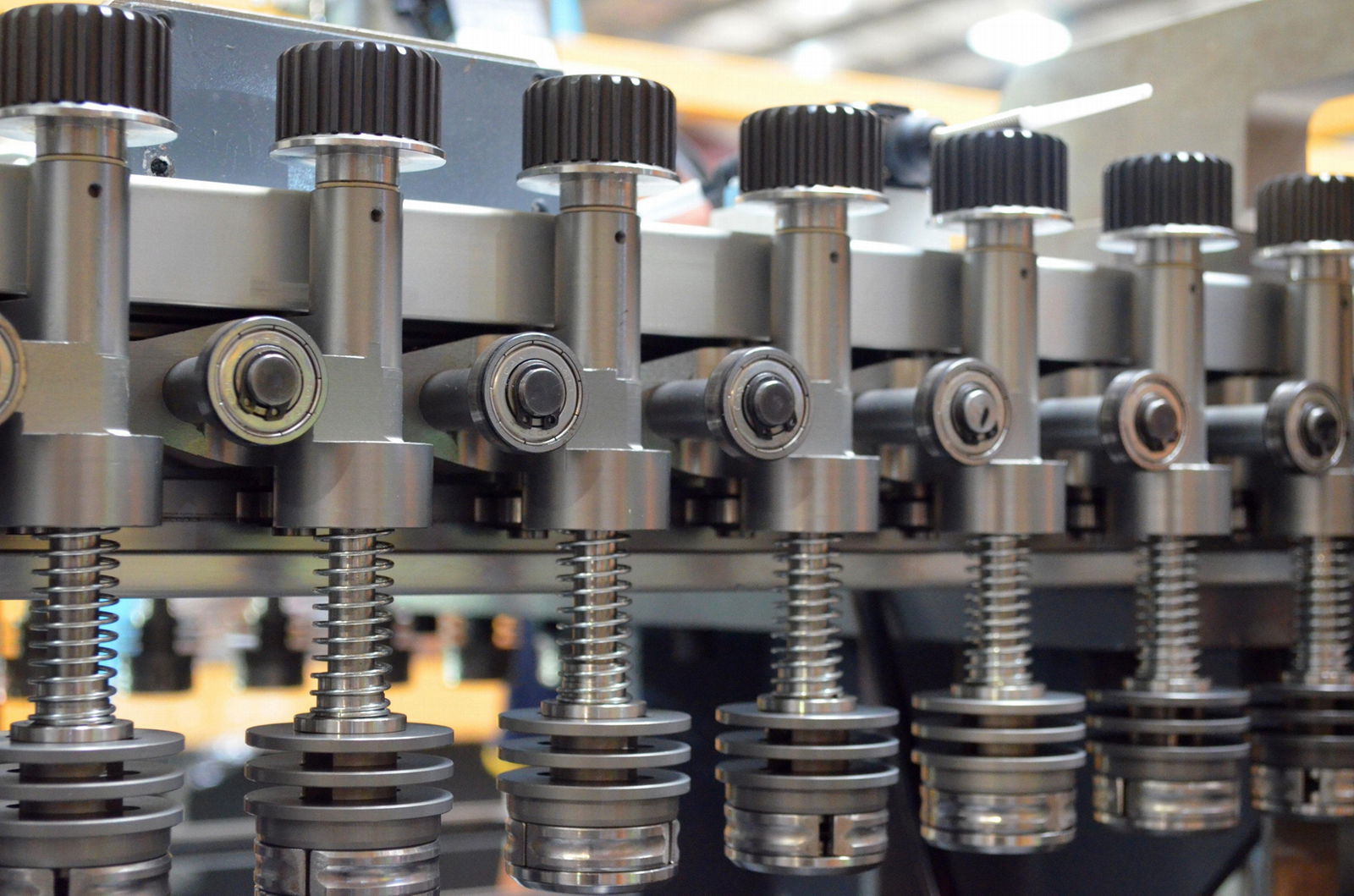

The simple, solid and reliable servo driven pitch changing system realizes the optimization of heating efficiency and the maximization of the diameter of the machinable bottle neck. Fast preform loading speed and accurate preform separation pitch. Servo drive mold clamping system. Bottom mold and clamping mold are linkage. Double-sided pneumatic pressurization compensation is to reduce running vibration and noise, improve the efficiency and stability of bottle blowing. Servo drives stretching rod, which can adjust the stretching curve on the human machine interface.

The servo drive unit is used for discharging bottles to the pneumatic conveyor, conveyor belt or vacuum conveyor.

Machine is equipped with high-pressure recovery system to reduce high-pressure gas consumption by about 30%.

|

|

Item

|

LXG-4/5

|

|

Main machine

|

Maximum Bottle capacity

|

6L

|

|

|

Maximum bottle diameter

|

Φ185mm

|

|

|

Neck diameter

|

Φ25~45mm

|

|

|

Maximum bottle height under neck

|

<380mm

|

|

|

Clamping stroke

|

200mm

|

|

|

Bottom die stroke

|

50mm

|

|

|

Bottle pitch

|

200mm

|

|

|

Maximum output rate (bph)

|

4000

|

|

|

Number of molds

|

4

|

|

Heating part

|

Number of heating modules

|

6

|

|

|

Number of heating lamps

|

9

|

|

|

Number of preform bases

|

108

|

|

Electric part

|

Voltage

|

380V

|

|

|

Frequency

|

50Hz

|

|

|

Service power

|

50~80kw/h

|

|

|

Installation power

|

160kw

|

|

Air source

|

High pressure

|

3.5Mpa

|

|

|

High pressure air consumption

|

12m³/min

|

|

Chilled water

(Water temperature ≤18℃)

|

Pressure

|

2~4bar

|

|

|

Flux

|

4-6m³/h

|

|

Chilled water

(Water temperature ≤30℃)

|

Pressure

|

2~4bar

|

|

|

Flux

|

6-9m³/h

|

|

Weight

|

G.W.

|

Around 10,000kg

|

|

Dimension

|

Main machine (L×W×H)

|

4900×2200×3200mm

|

|

|

Preform unscrambler(L×W×H)

|

2500×2500×3000mm

|

|

Remarks:

* 4000bph output rate base on 4.5L , 110 gram C’estbon water bottle.

* High pressure air consumption depends on PET bottle volume, altitude etc.

* With high-pressure air recycle system.

|

Payment Terms︰

TT/LC

Product Image